- Home

- About us

- Product info

- PRODUCTS DISTRIBUTION

- Aikoh Engineering Co., Ltd.

- AQUA SYSTEM Co.,Ltd

- CHUKYO KASEI KOGYO CO.,LTD. - 中京化成工業

- COCORESEARCH

- DAIDO MACHINES Co.,Ltd

- E LEAD

- ENOMOTOR MICRO PUMP MFG CO.,Ltd

- FESTO

- FREEBEAR

- HAYASHI DENKO

- HORIUCHI MACHINERY Co., Ltd

- HOZAN

- ICAN - shirakawadb

- ISHIZAKI ELECTRIC MFG.CO.,LTD

- JBJ BEARINGS

- JUKYO

- 2060 Free Flow Jukyo

- 2080 Free Flow Jukyo

- 2080 Sprocket Jukyo

- Aluminum Roller Free Flow Chain Jukyo

- Auto Lubricate Jukyo

- Ball Transfer Jukyo

- Blanced Type with Chain Drive

- Bracket Conveyor Jukyo

- Brush Type Oiler Jukyo

- Compound Mesh Belt

- Cool Forged Product Jukyo

- Customer-Made Roller Chain

- Double Pitch Chain Jukyo

- Drive Chain Jukyo

- Drive Dog Jukyo

- F Roller Conveyor Chain Jukyo

- Flange of UN406 JUKYO

- Free Flow Chain Jukyo

- Guide Roller Jukyo

- Heavy Duty Stainless Roller Chain Jukyo

- Light Duty Trolley Jukyo

- Load Trolley Jykyo

- RF12250 Side F Roller JUKYO

- Track of UN406 JUKYO

- Twin Bearing jUKYO

- UN300 & UN406 JUKYO

- UNI-7300 Jukyo

- X658 Series Overhead Conveyor Components Jukyo

- KANON NAKAMURA MFG., LTD

- KASHIYAMA INDUSTRIES.,LTD

- Kawasaki Tools

- Koang Yee

- Kondo Seisakusho Co., Ltd.

- KONSEI

- KOVAX Corporation

- KRIER-SAS

- KYOWA KOGYO CO. LTD

- Lobster CrimpingTool

- MAGMOTOR

- MAHR GROUP

- Myron L

- NA Co., Ltd

- NICHIDEN SHOKO

- Niika

- NITTO KOGYO CORPORATION

- Breakers, Switchgears, Terminal Blocks

- Control Panel Boards

- Distribution Board Parts

- Enclosures

- EV/PHEV General CHarging Stands

- High-voltage Power Receiving Equipment

- Home Panel Boards

- Optical Junction Boxes

- Plastic Enclosures

- Srandard Panel Boards

- System Racks

- Terminal box BP14-T4C

- Themal Management Product

- OIL FREE BEBICON HITACHI

- SANWA Tech.,Ins

- Shenzhen Miran Technology Co., Ltd.

- SHINANO

- SHIZUKI ELECTRIC

- SHUN FU MACHINERY CO., LTD

- 5 T Caterpiller Chains Shun Fu

- 5 T Roller Shun Fu

- 5T Chains (Heavy-duty vertical wheel) SHUN FU

- 5T Roller

- 5T Track Curve SHUN FU

- 5T Track Flange Ts - ShunFu

- 5T Trolley Chains (Middle wheel is the heavy-duty wheel, patent products) SHUN FU

- 5T Trolley Chains (Wheel is a conventional bearing wheel)

- 5T Trolley Chains (Wheel is a conventional bearing wheel) SHUN FU

- 5T Trolley Chains (Hight quality heavy-duty wheel) SHUN FU

- 5T Trolley Track Shun Fu

- 5T U Hanger (Type square) SHUN FU

- 5T Y Type Hanger Shun Fu

- 7T Caterpiller Chains Shun Fu

- 7T Up-Type Drive-unit Shun Fu

- 7T Roller Shun Fu

- Auto Lubricating Device Trolley Chains - ShunFu

- Auto Lubricating Machine - ShunFu

- Cross Swivel Hanger Of 5T Trolley Chains Shun Fu

- Cross Swivel With Oil Dropped Hanger Of 5T Trolley Chains Shun Fu

- Cross Swivel with U Type Hanger Shun Fu

- DOWN type 7 Trolley Chains (Heavy-duty wheel) Shun Fu

- DOWN type 7T Trolley Chains (Hight quality heavy-duty CNC wheel) Shun Fu

- DOWN type 7T Trolley Chains Shun Fu

- Electrode Pole Hanger Shun Fu

- Eng. Plastic Roller-ShunFu

- Gear Rotating Hanger Shun Fu

- Ground Rail Painting Chains Shun Fu

- Heavy Tape Take-up Device

- RF-05075R Chains (with A2 wing plate) - ShunFu

- RF-05100R Chains (with A2 wing plate) - ShunFu

- RF-05100R Roller Chains (with A2 wing plate) - ShunFu

- RF-05100R Roller Chains (without wing plate)-ShunFu

- RF-2080R Roller Chains (without wing plate) - ShunFu

- RF-2080R Roller Chains-ShunFu

- Track UP & Down Shun Fu

- Transmission system for 5T Link Belt Chains - ShunFu

- Transmission system for 7T Link Belt Chains - ShunFu

- U Hanger of 5 T Trolley Chains Shun Fu

- U Hanger of 5T Trolley Chains Shun Fu

- UP type 7T Trolley Chains (Hight quality heavy-duty wheel) Shun Fu

- UP type 7T Trolley Chains (with hanger) Shun Fu

- UP type 7T Trolley Chains (Hight quality heavy-duty wheel) Shun Fu

- Various Rapid Replacement Nozzle - ShunFu

- X348 Caterpiller Chains Shun Fu

- X348 Trolley conveyor system - ShunFu

- X458 Bracket & Chains (The unit is suitable for hanging autom car employed)-ShunFu

- X458 Caterpiller Chains Shun Fu

- SunnyKing

- TAEHUNG M&C

- TANIGUCHI HEATERS Co., Ltd.

- TELECRANE

- TOKYO - DIES

- Tokyo Hatsujyo

- VALQUA, LTD.

- WIN LING

- WUHAN MAXSINE ELECTRIC CO.,LTD

- WUXI XINJE ELECTRIC CO., LTD

- Xajong motor

- Yamaichi kako Co.,Ltd

- YAMAMOTOKEIKI

- YOKOIKIKAI

- MECHANICAL TRADING

- Abrasives 3M

- BELT - CUROA

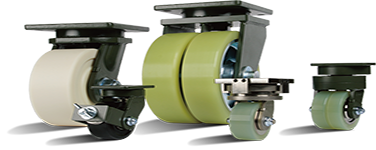

- CASTER WHEEL

- CONSUMABLE SUPPLIES

- ELECTRICAL EQUIPMENT

- FILM TO CHECK PRODUCT QUALITY

- FILTER

- HOLDER FOR E-SHAPED AND E-SHAPE RETAINER RING

- HYDRAULIC

- ICHINEN NX20

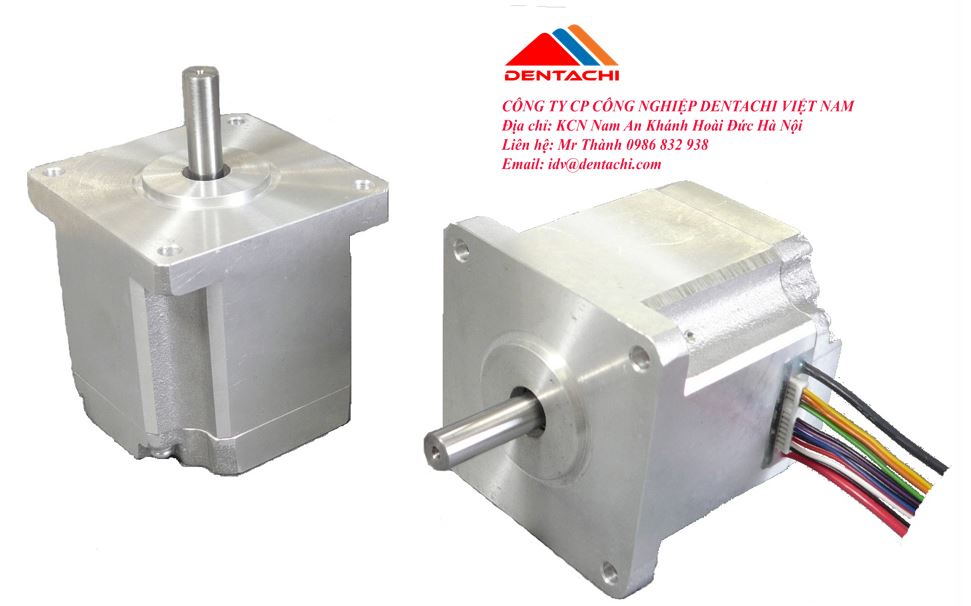

- MOTOR - PUMPS

- NABAKEM

- OFFICE TAPE

- OTHERs

- PIN GAUGE

- PNEUMATIC EQUIPMENT

- ROBOTIC DEBURRING TOOL

- ROLLER CHAIN

- SEMIKRON

- SPRING HOOK

- THERMAL HYGROMETER

- Valve

- WELDING ROD

- MECHANICAL MACHINING

- PRODUCTS DISTRIBUTION

- News

- Download Catalog

- Contact Us

- Language Menu

Motor Driver MD1D SAWAMURA

Motor Driver MD1D SAWAMURA

MD1D Series

Flexible customization is possible, including stable control performance, operating status output, and electromagnetic brake control.

MD3D Series

Driver for DC motors MM16F (2W) to SS23F (10W), SS32G (14W), and SS40E2 (DC24V only).

MS-100 Series

MD2A Series

This is a motor driver for the DC motor SS40E series (20W-80W) and SS60E (120W) series.

Product Information

| Format name | Rotation Direction | Input voltage (DC-V) |

Current Capacity (A) |

Speed Control | Torque control |

reference | ||||

| Voltage Control | Back electromotive force feedback control |

Encoder feedback control |

Tachometer generator feedback control |

Hall sensor feedback control |

||||||

| MD1D | reversible | 12, 24, 48 | 4–12 | ○ | ○※ | ○ | detail | |||

| MD3D | reversible | 12, 24 | 2 | ○ | ○※ | detail | ||||

| MD2A | reversible | AC100V | 2 | ○ | ○ | detail | ||||

| MS-100 | reversible | 8 to 32V | 5–25 | ○ | ○ | ○ | ○ | detail | ||

What is a motor driver?

The rotation speed of a DC motor can be increased or decreased by increasing or decreasing the applied voltage. In addition, the generated torque can be controlled by controlling the input current.

A motor driver uses this characteristic to control a DC motor. By using a

motor driver, you can control the motor's operation, as well as forward/reverse rotation (compatible models only) and protect the motor with protective functions.

Rotation direction

The direction of rotation of a DC motor can be reversed by reversing the polarity.

Reversible drivers have the function of switching output polarity, and can change the direction of rotation without contacts such as relays. This

function is essential for applications that require frequent forward and reverse rotation.

Current capacity

The current value of a DC motor varies depending on the size of the load. Conversely, if the current is limited, it will not be possible to drive a load greater than that.

When selecting a driver, it is necessary to consider not only the continuous rating of the motor, but also the operating time and required current of the motor to be used.

Related topic: Motor short-time rating (time-limited rating in the range exceeding the continuous rating)

Type of control (speed control and torque control)

Speed Control

The motor speed is controlled by controlling the voltage.

Torque Control

The output torque of the motor is controlled by controlling the current.

Types of speed control (voltage control and feedback control)

<Voltage control>

The rotation speed is increased or decreased by increasing or decreasing the voltage. This is the most basic control method.

<Feedback control>

The speed of a DC motor fluctuates depending on the size of the load. Therefore, it is not possible to keep the rotation speed constant by just controlling the voltage. Therefore, if the rotation speed of the motor is detected and the voltage is increased or decreased so that the speed matches the command value, the speed can be kept constant. This is feedback control. There are several types depending on what is used as the speed detector.

|

control

|

overview

|

Speed detector | Control Range | Speed fluctuation rate | Servo Lock |

| Back electromotive force feedback control |

Simple feedback control is performed by using the motor's back electromotive force. Since there is no speed detector, it is inexpensive but the effect is weak. |

Not required | 15:1 | ±15% |

-

|

| Encoder feedback control |

A motor with an encoder is used for feedback control. | Encoder | 100:1 | ±2% or less |

○

|

| Tachometer generator feedback control |

Feedback control is performed using a motor with a tachometer generator. | Tachogen | 100:1 | ±2% or less |

○

|

| Hall sensor feedback control |

Feedback control is performed using the signal from the Hall sensor built into the brushless DC motor to detect the magnetic poles . |

Related products

-

Product portfolio

- PRODUCTS DISTRIBUTION

- AQUA SYSTEM Co.,Ltd

- DAIDO MACHINES Co.,Ltd

- KANON NAKAMURA MFG., LTD

- ENOMOTOR MICRO PUMP MFG CO.,Ltd

- HORIUCHI MACHINERY Co., Ltd

- KASHIYAMA INDUSTRIES.,LTD

- TANIGUCHI HEATERS Co., Ltd.

- CHUKYO KASEI KOGYO CO.,LTD. - 中京化成工業

- Myron L

- OIL FREE BEBICON HITACHI

- WUXI XINJE ELECTRIC CO., LTD

- WUHAN MAXSINE ELECTRIC CO.,LTD

- KOVAX Corporation

- HAYASHI DENKO

- NITTO KOGYO CORPORATION

- SANWA Tech.,Ins

- NA Co., Ltd

- Yamaichi kako Co.,Ltd

- Shenzhen Miran Technology Co., Ltd.

- MAGMOTOR

- JBJ BEARINGS

- ISHIZAKI ELECTRIC MFG.CO.,LTD

- Kondo Seisakusho Co., Ltd.

- SHIZUKI ELECTRIC

- NICHIDEN SHOKO

- KRIER-SAS

- SHINANO

- Koang Yee

- YOKOIKIKAI

- FREEBEAR

- Tokyo Hatsujyo

- TAEHUNG M&C

- WIN LING

- TOKYO - DIES

- YAMAMOTOKEIKI

- FESTO

- SHUN FU MACHINERY CO., LTD

- Aikoh Engineering Co., Ltd.

- KYOWA KOGYO CO. LTD

- Lobster CrimpingTool

- JUKYO

- VALQUA, LTD.

- HOZAN

- ICAN - shirakawadb

- TELECRANE

- SunnyKing

- COCORESEARCH

- Kawasaki Tools

- MAHR GROUP

- Xajong motor

- KONSEI

- Niika

- E LEAD

- MECHANICAL TRADING

- SEMIKRON

- Abrasives 3M

- ELECTRICAL EQUIPMENT

- HYDRAULIC

- CASTER WHEEL

- MOTOR - PUMPS

- ICHINEN NX20

- NABAKEM

- CONSUMABLE SUPPLIES

- PNEUMATIC EQUIPMENT

- BELT - CUROA

- FILTER

- PIN GAUGE

- OTHERs

- WELDING ROD

- OFFICE TAPE

- ROLLER CHAIN

- THERMAL HYGROMETER

- FILM TO CHECK PRODUCT QUALITY

- SPRING HOOK

- HOLDER FOR E-SHAPED AND E-SHAPE RETAINER RING

- ROBOTIC DEBURRING TOOL

- Valve

- MECHANICAL MACHINING

- PRODUCTS DISTRIBUTION

News

Online Support